“World Leaders in the Field of Air Abrasion Technology”

Expertise that pays off today.

Expertise that pays off today.

For decades, Crystal Mark Incorporated has developed and refined the air abrasion process for aerospace, semiconductor and other high technology disciplines. Crystalmark Dental Systems brings all that experience to bear with the highly evolved CrystalAir™ Intraoral Air Abrasion Unit. CrystalAir™ gives dentists a greater level of control for a wider range of treatment scenarios with a unit that is technologically superior and of greater value than that of the competition.

History of Air Abrasion

Air abrasion technology was initially developed in the 1940s by Dr. Robert Black, specifically, for dental cavity preparation. Unfortunately, the restorative techniques and materials available at that time involved the use of silver amalgam, gold or acrylic. These restorative materials did not lend themselves to the type and form of cavity preparation generated by air abrasion. This factor, combined with the introduction of the high speed turbine handpiece in the 1950s and no high velocity suction, essentially pushed air abrasion out of the limelight until its resurgence in the early 1990s.

Crystal Mark’s Beginnings

While the use of air abrasion in dentistry was fading in the late 1950s, applications for this unique technology were being developed in other disciplines, primarily industrial in nature. Ernest Swan, the founder of Crystal Mark, Inc. (the industrial division), pioneered many of these non-dental applications and formed his own company in 1967. Today, the company is owned and operated by his three sons who are now joined by two of his grandsons. Crystal Mark, Inc. continues to lead the way in new and innovative applications for air abrasion technology.

While the use of air abrasion in dentistry was fading in the late 1950s, applications for this unique technology were being developed in other disciplines, primarily industrial in nature. Ernest Swan, the founder of Crystal Mark, Inc. (the industrial division), pioneered many of these non-dental applications and formed his own company in 1967. Today, the company is owned and operated by his three sons who are now joined by two of his grandsons. Crystal Mark, Inc. continues to lead the way in new and innovative applications for air abrasion technology.

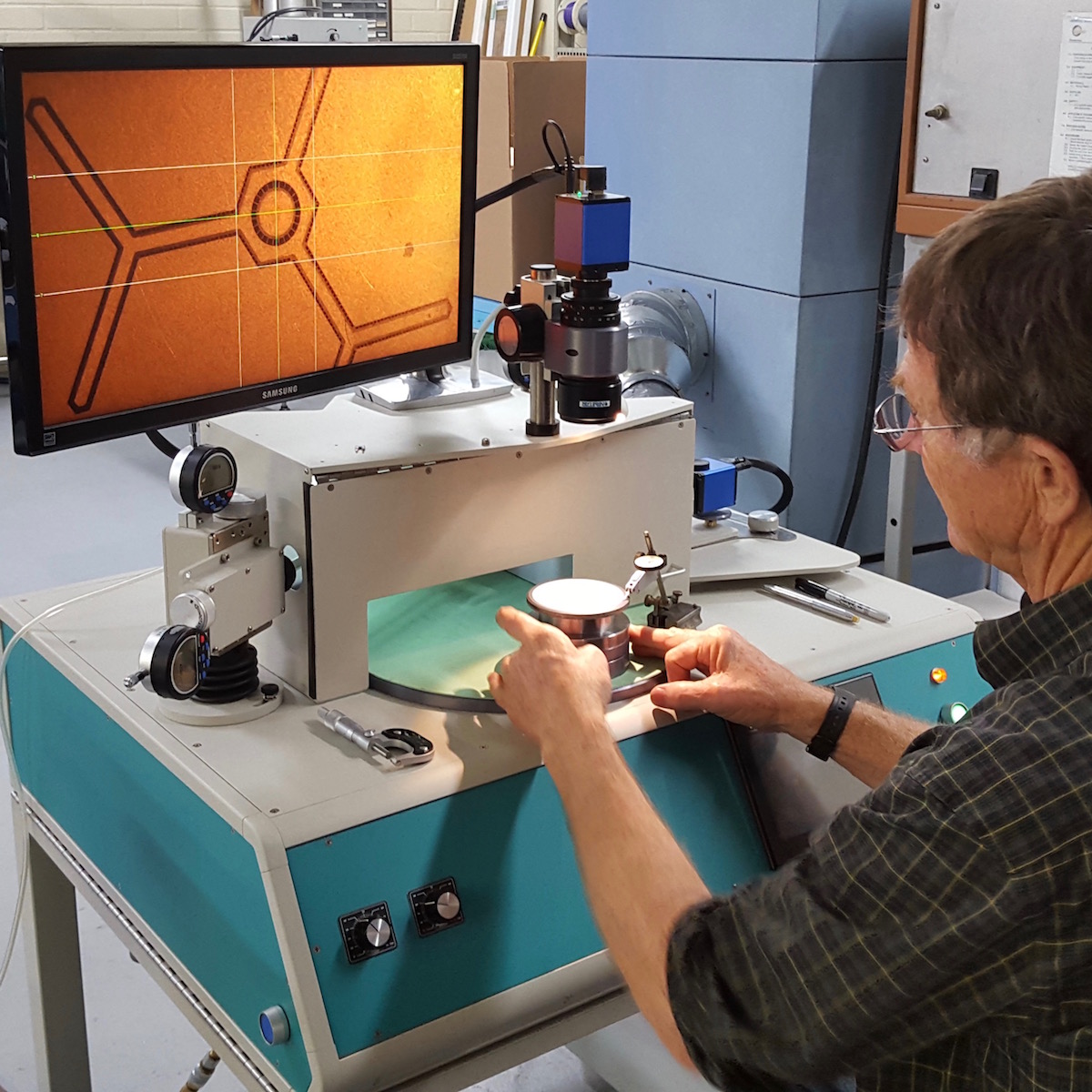

Crystal Mark not only manufactures air abrasion equipment and supplies, but it also offers “job shop” and process development services in its Glendale, California facility. While this service offers air abrasion technology to customers it also gives Crystal Mark opportunities to discover new applications, refinements, and solutions in air abrasion technology. Some of the industries that benefited from air abrasion’s Applications from the precision surface finishing of semiconductor wafers to selective matrix removal from priceless fossils such as dinosaur bones has given Crystal Mark a far-reaching knowledge base and an understanding of the intricate details of applied air abrasion technology.

Today, with the development and refinement of composite restorative materials combined with the public demand for more conservative treatment options, dentists who want to practice minimally invasive dentistry recognize air abrasion to be absolutely essential in attaining the best results for adhesive bonding preparation, and a growing number of those clinicians will tell you that Crystalmark Dental makes the very best air abrasion unit available at any price.

From Dinosaurs to Dentistry

Many applications – total control.

Examples of some of the applications that air abrasion is used for.

Some of the industries which benefited from air abrasion’s beginnings were high technology fields such as the semiconductor fabrication industry. The world of paleontology also derived spin-off benefits from this technology. Applications from the precision surface finishing of semiconductor wafers to selective matrix removal from priceless fossils such as dinosaur bones has given Crystal Mark a far-reaching knowledge base and an understanding of the intricate details of applied air abrasion technology.

Today, with the development of composite restorative materials and the public demand for better more conservative treatment options, the dental profession is seeing a resurgence of the air abrasion modality for cavity preparation. Crystal Mark has been at the forefront of all other air abrasion applications for the last 30 years. We feel that it is only fitting that we return to our “roots”, and give back to the dental profession the very best in air abrasion technology. It is towards this end, that we have designed our line of continually evolving and extremly successful dental air abrasion products.

Today, with the development of composite restorative materials and the public demand for better more conservative treatment options, the dental profession is seeing a resurgence of the air abrasion modality for cavity preparation. Crystal Mark has been at the forefront of all other air abrasion applications for the last 30 years. We feel that it is only fitting that we return to our “roots”, and give back to the dental profession the very best in air abrasion technology. It is towards this end, that we have designed our line of continually evolving and extremly successful dental air abrasion products.